Our SUT Finisher is a development of Schmitt Ultraschalltechnik and our chemistry supplier BCD. It is available as spray and as a liquid for dipping the parts. The Finisher eliminates the discomfort, normally arising when using Aceton to smoothen the surfaces of ABS and ABS+ 3D prints. The parts can be lightly sprayed or completely dipped into the liquid, which dissolves the top surface and achieves the desired smoothing.

To prevent multiple spray or dipping applicationswe recommend to slightly grind the print level structures using abrasive paper. After applying the SUT finisher the parts merely need to dry. The drying time is approximately 2 hours.

Of course you still need o follow certain safety instructions – your health is important to us!

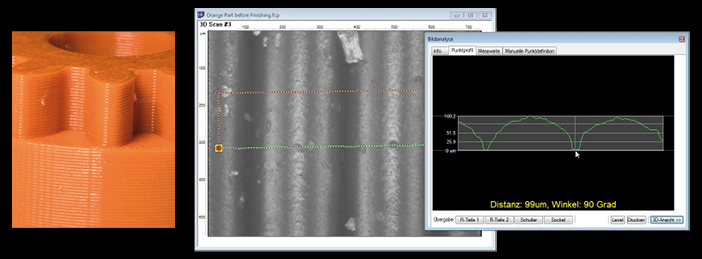

3D-Scan Analysis of an ABS print top surface before applying the SUT finisher spray.

The layer structure is clearly visible and shows a maximum depth of approx. 100 µm.

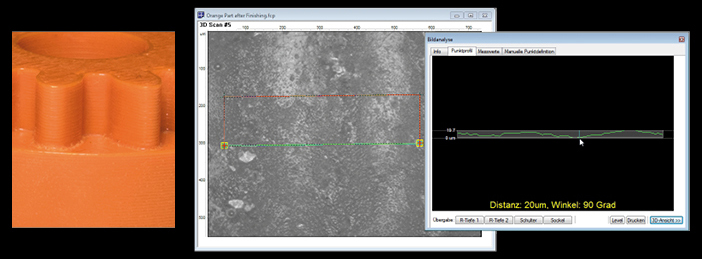

3D-Scan Analysis of an ABS print top surface after applying the SUT finisher spray.

The layer structure is almost completely flattened and now shows a maximum depth of approx. 20 µm.

Examples of smoothed ABS prints

The smoothing result of the surfaces is satisfying.The form shown in most right image was printed in two parts, which were glued together by applying a small amount of SUT Finisher (similar to cold welding).